LMP机床高压冷却泵

产品简介

详细信息

LMP机床高压冷却泵

应用于深孔加工的数控机床高压主轴内冷系统,包括相连通的一级过滤机构、二级过滤结构和三级过滤机构,一级过滤机构的入口与机床排屑槽相连通,三级过滤机构的出口与一高压泵组的入口相连通,高压泵组的出口连接有旋转接头,旋转接头安装在机床主轴尾部,旋转接头用于向深孔加工刀具提供来自高压泵组的压力在7MPa以上的高压切削液,经深孔加工刀具喷出的切削液由机床排屑槽收集;安装使用后,来自机床排屑槽的切削液先后经过一级过滤机构、二级过滤结构和三级过滤机构的层层过滤净化并由高压泵组增压至7MPa以上,最终通过旋转接头输送给深孔

LMP1280GWR262P02BA, LMP1280GWR262P02BC, LMP1280GWR262P02BF, LMP1280GWR262P02BK,

LMP1290GWR262P02BA, LMP1290GWR262P02BC, LMP1290GWR262P02BF, LMP1290GWR262P02BK,

LMP1350GWR262P02BA, LMP1350GWR262P02BC, LMP1350GWR262P02BF, LMP1350GWR262P02BK,

LMP1360GWR262P02BA, LMP1360GWR262P02BC, LMP1360GWR262P02BF, LMP1360GWR262P02BK,

LMP1270GGR262P02BA, LMP1270GGR262P02BC, LMP1270GGR262P02BF, LMP1270GGR262P02BK,

LMP1280GGR262P02BA, LMP1280GGR262P02BC, LMP1280GGR262P02BF, LMP1280GGR262P02BK,

LMP1290GGR262P02BA, LMP1290GGR262P02BC, LMP1290GGR262P02BF, LMP1290GGR262P02BK,

LMP1350GGR262P02BA, LMP1350GGR262P02BC, LMP1350GGR262P02BF, LMP1350GGR262P02BK,

LMP1360GGR262P02BA, LMP1360GGR262P02BC, LMP1360GGR262P02BF, LMP1360GGR262P02BK,

LMP1040GWT219Lxx, LMP1050GWT219Lxx, LMP1140GWT219Lxx, LMP2030GWT219Lxx,

LMP2130GWT219Lxx, LMP2220GWT219Lxx, LMP1040GGT219Lxx, LMP1050GGT219Lxx,

LMP1140GGT219Lxx, LMP2030GGT219Lxx,

LMP2130GGT219Lxx, LMP2220GGT219Lxx,

FAQ Aiken Pumps

Here you can find answers of questions about Aiken Screw Pumps

How they work

Design features

Liquids

Electrical parameters

Approval

If you have any more questions, please contact us via our contact form.

Show all / Hide all

Are Aiken Screw Pumps ATEX approved?

Aiken ink pumps (PAB und PNB) are ATEX approved – they are correspondingly certified and marked. The respective certificates of conformity and prototype test certificates / confirmation of deposit are available for both pump series and can be requested.

Are Aiken Screw Pumps UL or CSA approved?

The drive motors conform to VDE regulations as well as European motor standards (DIN EN 60 034-1) and bear a CE mark.

Versions compliant with non-European regulations, e.g. CSA, UL or other country-specific requirements are possible.

What do you have to pay attention to when using frequency converters?

When frequency converters are used make sure that RC elements provide for interference suppression and, as the case may be, for voltage smoothing.

In principle, thermistor-type motor protection can only be achieved with the use of thermal sensors (PTC) with a corresponding tripping unit.

Are Aiken Screw Pumps suitable for use with frequency converters?

In general, our pump drives can be outfitted for operation with frequency converters.

What do you have to pay attention to in the case of different mains voltages?

Standard Aiken Pumps have to run on mains voltages conforming to IEC38.

When pumps are used with non-European electrical parameters it is necessary to remember that the frequency and voltage are in direct proportion to each other.

Pump drives and/or hydraulic elements are adjusted at the factory to make sure the required delivery parameters are reached even at different frequencies.

You can find the respective characteristics in our brochures.

What are the maximum viscosities a liquid can have?

Unless otherwise indicated, the characteristic curves shown in the brochures apply to viscosities of 1 mm²/s at a density of 1kg/dm³.

But selected types of pumps also permit higher viscosities. You can find more precise information in our brochures. The maximum viscosities amount to the following in the case of:

centrifugal pumps: 20 mm²/s

positive-displacement pumps: 2,500 mm²/s

Higher viscosities are available on request.

What is the maximum contamination permitted for a liquid?

Due to the design of individual pumps it is possible to permit varying degrees of contaminants in the liquid being pumped. So it is possible to pump clean, turbid and dirty liquids.

The following applies to centrifugal pumps: contaminant grain sizes of 0.3 mm to 8 mm are permissible, depending on the type of pump. In this respect the lower values apply to closed impellers and the higher values to open ones.

Another factor is the quantity of the contaminants found in the liquid. Here, too, the following applies: large quantities of contaminants require the use of open impellers.

The following applies to screw pumps: due to the way they work, only clean liquids without abrasive or long-fibered constituents (contaminated with a maximum grain size of 0.05 mm at a maximum of 40 mg/l) are permitted in the case of screw pumps.

For more information please contact us.

What is the maximum temperature the liquid can have?

For every type of pump there are restrictions on the temperature of the pumped liquids due to the materials used. You can find concrete information on this in the respective brochures.

Among the plastic pumps there are ones that are limited to temperatures of -30 °C to +60 °C. This range is expanded to limits of -100 °C to +150 °C by the use of a special plastic.

Limits of -30 °C to +90 °C generally apply in the case of pumps made of metal. With special version it is possible to extend this range to -70 °C to +170 °C.

What liquids is it possible to pump?

Aiken Pumps are used for a large number of industrial liquids.

They include, among others, emulsions, cooling brines, lacquers, lyes, inks that contain solvents, oils, organic solutions, cleansers, acids, lubricants, thermal oils, water (distilled or deionized) and water-based paints.

The liquids that can be used in concrete cases depend on the pump. You can find information on this in the respective brochures, or you can contact us.

Are Aiken Pumps self-priming?

Our screw pumps are self-priming due to the way they work.

Sealless Aiken immersion pumps are basically not self-priming. The 1st impeller has to be wetted for the starting procedure.

Why is it necessary to check the direction of rotation?

Due to the way they work, centrifugal pumps even deliver when they are run opposite to the specified direction of rotation. But only 1/3 of the required volumetric flow is reached. Damage to the pump due to the wrong direction of rotation can be largely ruled out.

The direction of rotation in the case of screw pumps is much more critical. They are destroyed if they are run in the wrong direction of rotation. If no liquid is delivered and there is thus no lubrication of the pump’s hydraulic system, the pump will run

"dry". The drastic increase in temperature of the hydraulic components leads to immediate and irreparable destruction of the screws and the casing’s coating.

Are all Aiken Pumps sealless?

All Aiken centrifugal pumps (immersion pumps) are sealless.

One exception is our LMP screw pumps. These positivedisplacement pumps come with shaft seals or mechanical seals to that they can work dependably even at pressures of 120 bars.

Do sealless Aiken immersion pumps have to be immersed in a tank?

All our sealless centrifugal pumps have to be immersed in a tank (not to be confused with submersible-motor pumps where the complete pump together with its motor is immersed in the liquid). Design-related leakage makes a tank absolutely necessary.

What is a sealless immersion pump?

Pumps generally require a shaft seal. These shaft seals are very sensitive to contaminated liquids and dry running. So the seal is the main wearing part of a pump.

Most pump failures are due to defective seals.

The design of sealless pumps makes it possible to dispense with a shaft seal. With these pumps the impeller sits on an extended motor shaft. Since it is used as an immersion pump, the controlled leakage remains in the tank or reservoir.

Thanks to the sealless design of Aiken immersion pumps it is possible for them to run dry to limited extent.

Aiken Pumps is one of the few manufacturers worldwide able to make sealless pumps that are reliable at operating pressures as high as 25 bars.

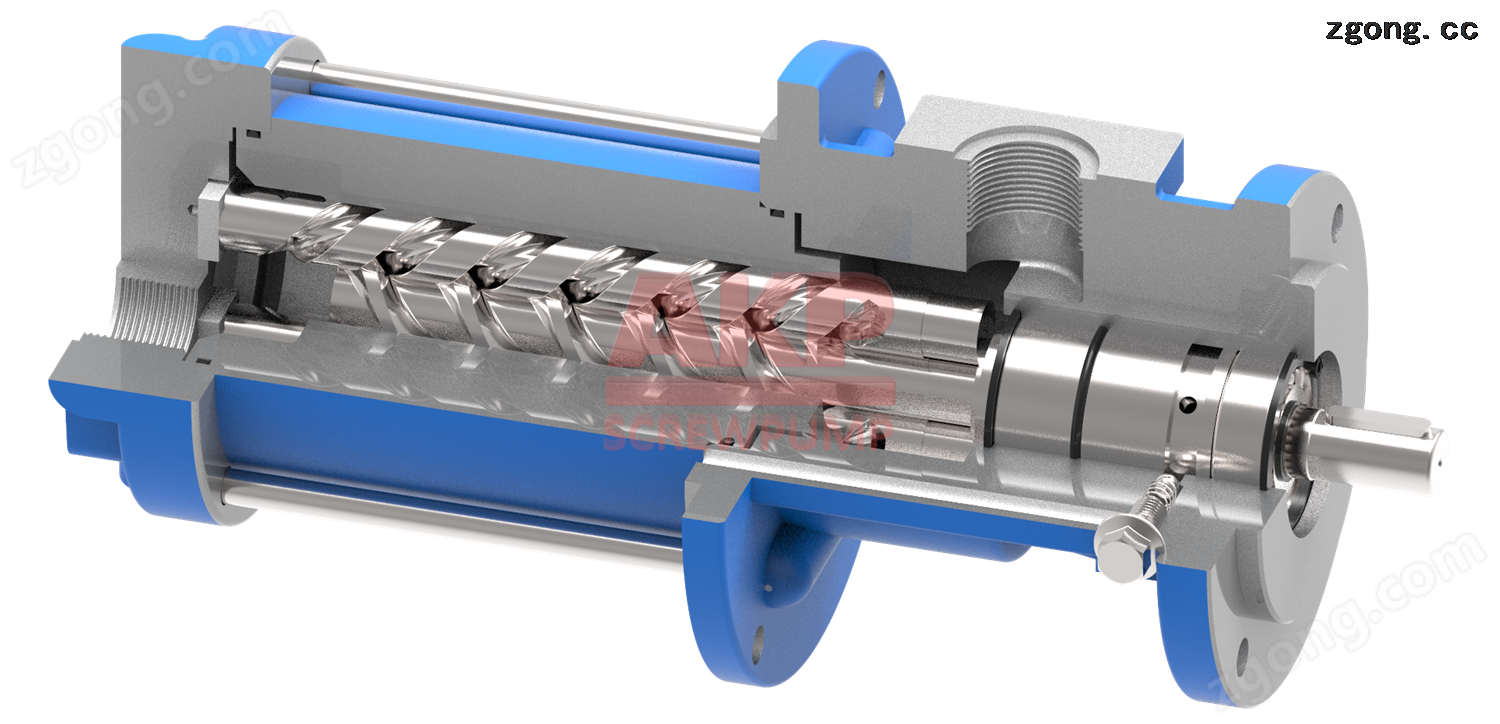

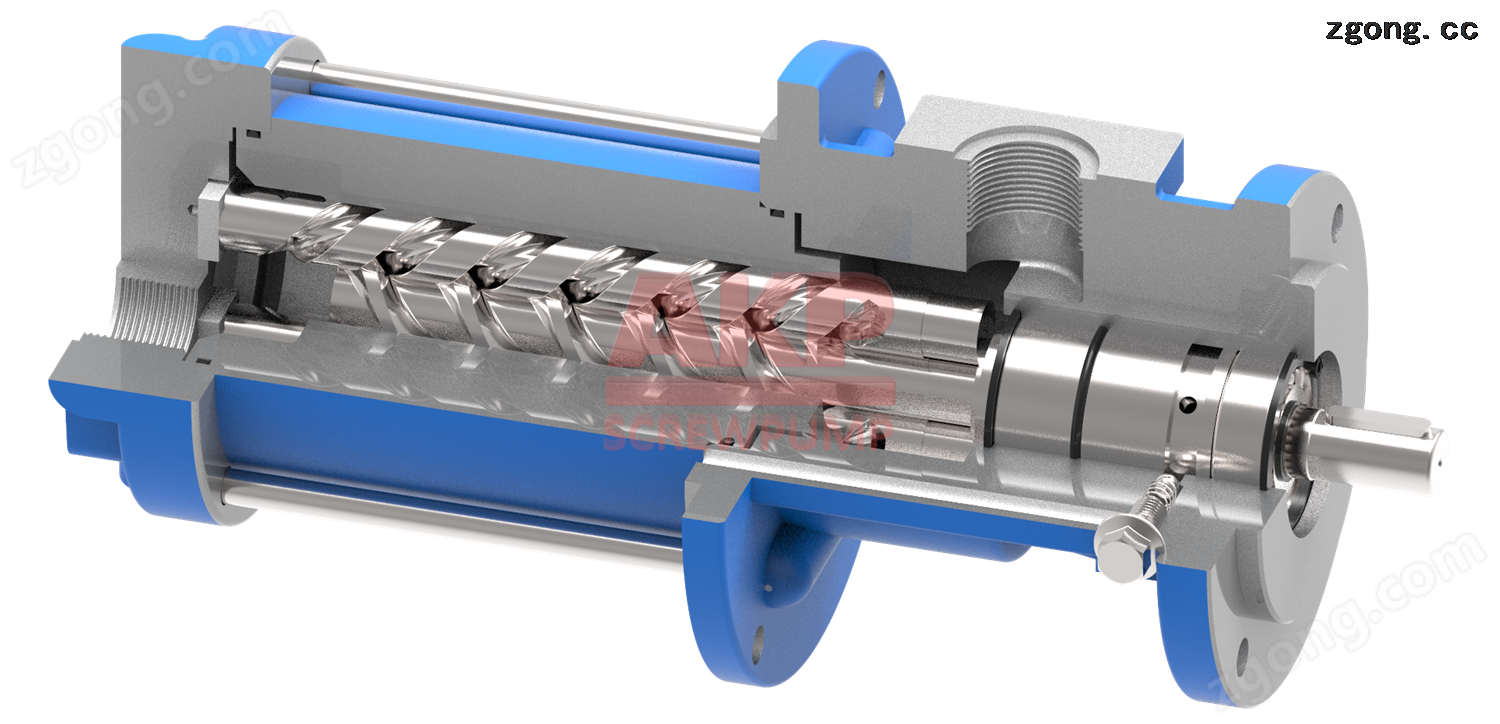

How does a screw pump work?

With this pump there are three screws next to each other in the discharge casing. The primary screw, or drive screw, in the middle forms the pumping cavity together with the two secondary screws when they mesh.

The rotation of the set of screws opens up cavities on the suction side which the liquid in the pump flows into. The liquid is forced via the screws’ angular momentum through the closing cavities to the pump’s pressure port.

Since this principle corresponds to a piston constantly moving in one direction, the result is an even, surge-free volumetric flow.

The maximum achievable pressure is limited by the mechanical strength of the components, but primarily by the motor power.

LMP1270GWR262P02BA, LMP1270GWR262P02BC, LMP1270GWR262P02BF, LMP1270GWR262P02BK, LMP1280GWR262P02BA, LMP1280GWR262P02BC, LMP1280GWR262P02BF, LMP1280GWR262P02BK, LMP1290GWR262P02BA, LMP1290GWR262P02BC, LMP1290GWR262P02BF, LMP1290GWR262P02BK, LMP1350GWR262P02BA, LMP1350GWR262P02BC, LMP1350GWR262P02BF, LMP1350GWR262P02BK, LMP1360GWR262P02BA, LMP1360GWR262P02BC, LMP1360GWR262P02BF, LMP1360GWR262P02BK, LMP1270GGR262P02BA, LMP1270GGR262P02BC, LMP1270GGR262P02BF, LMP1270GGR262P02BK, LMP1280GGR262P02BA, LMP1280GGR262P02BC, LMP1280GGR262P02BF, LMP1280GGR262P02BK, LMP1290GGR262P02BA, LMP1290GGR262P02BC, LMP1290GGR262P02BF, LMP1290GGR262P02BK, LMP1350GGR262P02BA, LMP1350GGR262P02BC, LMP1350GGR262P02BF, LMP1350GGR262P02BK, LMP1360GGR262P02BA, LMP1360GGR262P02BC, LMP1360GGR262P02BF, LMP1360GGR262P02BK

LMP1040GWT219Lxx, LMP1050GWT219Lxx, LMP1140GWT219Lxx,

LMP2030GWT219Lxx, LMP2130GWT219Lxx, LMP2220GWT219Lxx,

LMP1040GGT219Lxx, LMP1050GGT219Lxx,

LMP1140GGT219Lxx, LMP2030GGT219Lxx,LMP2130GGT219Lxx, LMP2220GGT219Lxx,

LMP1210GWT262Kxx,LMP1310GWT262Kxx, LMP1210GGT262Kxx, LMP1310GGT262Kxx

»展示技术细节

LMP1270GWR262P02BA, LMP1270GWR262P02BC, LMP1270GWR262P02BF, LMP1270GWR262P02BK,

LMP1280GWR262P02BA, LMP1280GWR262P02BC, LMP1280GWR262P02BF, LMP1280GWR262P02BK,

LMP1290GWR262P02BA, LMP1290GWR262P02BC, LMP1290GWR262P02BF, LMP1290GWR262P02BK,

LMP1350GWR262P02BA, LMP1350GWR262P02BC, LMP1350GWR262P02BF, LMP1350GWR262P02BK,

LMP1360GWR262P02BA, LMP1360GWR262P02BC, LMP1360GWR262P02BF, LMP1360GWR262P02BK,

LMP1270GGR262P02BA, LMP1270GGR262P02BC, LMP1270GGR262P02BF, LMP1270GGR262P02BK,

LMP1280GGR262P02BA, LMP1280GGR262P02BC, LMP1280GGR262P02BF, LMP1280GGR262P02BK,

LMP1290GGR262P02BA, LMP1290GGR262P02BC, LMP1290GGR262P02BF, LMP1290GGR262P02BK,

LMP1350GGR262P02BA, LMP1350GGR262P02BC, LMP1350GGR262P02BF, LMP1350GGR262P02BK,

LMP1360GGR262P02BA, LMP1360GGR262P02BC, LMP1360GGR262P02BF, LMP1360GGR262P02BK,

LMP1040GWT219Lxx, LMP1050GWT219Lxx, LMP1140GWT219Lxx, LMP2030GWT219Lxx,

LMP2130GWT219Lxx, LMP2220GWT219Lxx, LMP1040GGT219Lxx, LMP1050GGT219Lxx,

LMP1140GGT219Lxx, LMP2030GGT219Lxx,

LMP2130GGT219Lxx, LMP2220GGT219Lxx,

FAQ Aiken Pumps

Here you can find answers of questions about Aiken Screw Pumps

How they work

Design features

Liquids

Electrical parameters

Approval

If you have any more questions, please contact us via our contact form.

Show all / Hide all

Are Aiken Screw Pumps ATEX approved?

Aiken ink pumps (PAB und PNB) are ATEX approved – they are correspondingly certified and marked. The respective certificates of conformity and prototype test certificates / confirmation of deposit are available for both pump series and can be requested.

Are Aiken Screw Pumps UL or CSA approved?

The drive motors conform to VDE regulations as well as European motor standards (DIN EN 60 034-1) and bear a CE mark.

Versions compliant with non-European regulations, e.g. CSA, UL or other country-specific requirements are possible.

What do you have to pay attention to when using frequency converters?

When frequency converters are used make sure that RC elements provide for interference suppression and, as the case may be, for voltage smoothing.

In principle, thermistor-type motor protection can only be achieved with the use of thermal sensors (PTC) with a corresponding tripping unit.

Are Aiken Screw Pumps suitable for use with frequency converters?

In general, our pump drives can be outfitted for operation with frequency converters.

What do you have to pay attention to in the case of different mains voltages?

Standard Aiken Pumps have to run on mains voltages conforming to IEC38.

When pumps are used with non-European electrical parameters it is necessary to remember that the frequency and voltage are in direct proportion to each other.

Pump drives and/or hydraulic elements are adjusted at the factory to make sure the required delivery parameters are reached even at different frequencies.

You can find the respective characteristics in our brochures.

What are the maximum viscosities a liquid can have?

Unless otherwise indicated, the characteristic curves shown in the brochures apply to viscosities of 1 mm²/s at a density of 1kg/dm³.

But selected types of pumps also permit higher viscosities. You can find more precise information in our brochures. The maximum viscosities amount to the following in the case of:

centrifugal pumps: 20 mm²/s

positive-displacement pumps: 2,500 mm²/s

Higher viscosities are available on request.

What is the maximum contamination permitted for a liquid?

Due to the design of individual pumps it is possible to permit varying degrees of contaminants in the liquid being pumped. So it is possible to pump clean, turbid and dirty liquids.

The following applies to centrifugal pumps: contaminant grain sizes of 0.3 mm to 8 mm are permissible, depending on the type of pump. In this respect the lower values apply to closed impellers and the higher values to open ones.

Another factor is the quantity of the contaminants found in the liquid. Here, too, the following applies: large quantities of contaminants require the use of open impellers.

The following applies to screw pumps: due to the way they work, only clean liquids without abrasive or long-fibered constituents (contaminated with a maximum grain size of 0.05 mm at a maximum of 40 mg/l) are permitted in the case of screw pumps.

For more information please contact us.

What is the maximum temperature the liquid can have?

For every type of pump there are restrictions on the temperature of the pumped liquids due to the materials used. You can find concrete information on this in the respective brochures.

Among the plastic pumps there are ones that are limited to temperatures of -30 °C to +60 °C. This range is expanded to limits of -100 °C to +150 °C by the use of a special plastic.

Limits of -30 °C to +90 °C generally apply in the case of pumps made of metal. With special version it is possible to extend this range to -70 °C to +170 °C.

What liquids is it possible to pump?

Aiken Pumps are used for a large number of industrial liquids.

They include, among others, emulsions, cooling brines, lacquers, lyes, inks that contain solvents, oils, organic solutions, cleansers, acids, lubricants, thermal oils, water (distilled or deionized) and water-based paints.

The liquids that can be used in concrete cases depend on the pump. You can find information on this in the respective brochures, or you can contact us.

Are Aiken Pumps self-priming?

Our screw pumps are self-priming due to the way they work.

Sealless Aiken immersion pumps are basically not self-priming. The 1st impeller has to be wetted for the starting procedure.

Why is it necessary to check the direction of rotation?

Due to the way they work, centrifugal pumps even deliver when they are run opposite to the specified direction of rotation. But only 1/3 of the required volumetric flow is reached. Damage to the pump due to the wrong direction of rotation can be largely ruled out.

The direction of rotation in the case of screw pumps is much more critical. They are destroyed if they are run in the wrong direction of rotation. If no liquid is delivered and there is thus no lubrication of the pump’s hydraulic system, the pump will run

"dry". The drastic increase in temperature of the hydraulic components leads to immediate and irreparable destruction of the screws and the casing’s coating.

Are all Aiken Pumps sealless?

All Aiken centrifugal pumps (immersion pumps) are sealless.

One exception is our LMP screw pumps. These positivedisplacement pumps come with shaft seals or mechanical seals to that they can work dependably even at pressures of 120 bars.

Do sealless Aiken immersion pumps have to be immersed in a tank?

All our sealless centrifugal pumps have to be immersed in a tank (not to be confused with submersible-motor pumps where the complete pump together with its motor is immersed in the liquid). Design-related leakage makes a tank absolutely necessary.

What is a sealless immersion pump?

Pumps generally require a shaft seal. These shaft seals are very sensitive to contaminated liquids and dry running. So the seal is the main wearing part of a pump.

Most pump failures are due to defective seals.

The design of sealless pumps makes it possible to dispense with a shaft seal. With these pumps the impeller sits on an extended motor shaft. Since it is used as an immersion pump, the controlled leakage remains in the tank or reservoir.

Thanks to the sealless design of Aiken immersion pumps it is possible for them to run dry to limited extent.

Aiken Pumps is one of the few manufacturers worldwide able to make sealless pumps that are reliable at operating pressures as high as 25 bars.

How does a screw pump work?

With this pump there are three screws next to each other in the discharge casing. The primary screw, or drive screw, in the middle forms the pumping cavity together with the two secondary screws when they mesh.

The rotation of the set of screws opens up cavities on the suction side which the liquid in the pump flows into. The liquid is forced via the screws’ angular momentum through the closing cavities to the pump’s pressure port.

Since this principle corresponds to a piston constantly moving in one direction, the result is an even, surge-free volumetric flow.

The maximum achievable pressure is limited by the mechanical strength of the components, but primarily by the motor power.

LMP1270GWR262P02BA, LMP1270GWR262P02BC, LMP1270GWR262P02BF, LMP1270GWR262P02BK, LMP1280GWR262P02BA, LMP1280GWR262P02BC, LMP1280GWR262P02BF, LMP1280GWR262P02BK, LMP1290GWR262P02BA, LMP1290GWR262P02BC, LMP1290GWR262P02BF, LMP1290GWR262P02BK, LMP1350GWR262P02BA, LMP1350GWR262P02BC, LMP1350GWR262P02BF, LMP1350GWR262P02BK, LMP1360GWR262P02BA, LMP1360GWR262P02BC, LMP1360GWR262P02BF, LMP1360GWR262P02BK, LMP1270GGR262P02BA, LMP1270GGR262P02BC, LMP1270GGR262P02BF, LMP1270GGR262P02BK, LMP1280GGR262P02BA, LMP1280GGR262P02BC, LMP1280GGR262P02BF, LMP1280GGR262P02BK, LMP1290GGR262P02BA, LMP1290GGR262P02BC, LMP1290GGR262P02BF, LMP1290GGR262P02BK, LMP1350GGR262P02BA, LMP1350GGR262P02BC, LMP1350GGR262P02BF, LMP1350GGR262P02BK, LMP1360GGR262P02BA, LMP1360GGR262P02BC, LMP1360GGR262P02BF, LMP1360GGR262P02BK

LMP1040GWT219Lxx, LMP1050GWT219Lxx, LMP1140GWT219Lxx, LMP2030GWT219Lxx, LMP2130GWT219Lxx, LMP2220GWT219Lxx, LMP1040GGT219Lxx, LMP1050GGT219Lxx,

LMP1140GGT219Lxx, LMP2030GGT219Lxx,

LMP2130GGT219Lxx, LMP2220GGT219Lxx,

LMP1210GWT262Kxx,LMP1310GWT262Kxx, LMP1210GGT262Kxx, LMP1310GGT262Kxx

LMP1280GWR262P02BA, LMP1280GWR262P02BC, LMP1280GWR262P02BF, LMP1280GWR262P02BK,

LMP1290GWR262P02BA, LMP1290GWR262P02BC, LMP1290GWR262P02BF, LMP1290GWR262P02BK,

LMP1350GWR262P02BA, LMP1350GWR262P02BC, LMP1350GWR262P02BF, LMP1350GWR262P02BK,

LMP1360GWR262P02BA, LMP1360GWR262P02BC, LMP1360GWR262P02BF, LMP1360GWR262P02BK,

LMP1270GGR262P02BA, LMP1270GGR262P02BC, LMP1270GGR262P02BF, LMP1270GGR262P02BK,

LMP1280GGR262P02BA, LMP1280GGR262P02BC, LMP1280GGR262P02BF, LMP1280GGR262P02BK,

LMP1290GGR262P02BA, LMP1290GGR262P02BC, LMP1290GGR262P02BF, LMP1290GGR262P02BK,

LMP1350GGR262P02BA, LMP1350GGR262P02BC, LMP1350GGR262P02BF, LMP1350GGR262P02BK,

LMP1360GGR262P02BA, LMP1360GGR262P02BC, LMP1360GGR262P02BF, LMP1360GGR262P02BK,

LMP1040GWT219Lxx, LMP1050GWT219Lxx, LMP1140GWT219Lxx, LMP2030GWT219Lxx,

LMP2130GWT219Lxx, LMP2220GWT219Lxx, LMP1040GGT219Lxx, LMP1050GGT219Lxx,

LMP1140GGT219Lxx, LMP2030GGT219Lxx,

LMP2130GGT219Lxx, LMP2220GGT219Lxx,

FAQ Aiken Pumps

Here you can find answers of questions about Aiken Screw Pumps

How they work

Design features

Liquids

Electrical parameters

Approval

If you have any more questions, please contact us via our contact form.

Show all / Hide all

Are Aiken Screw Pumps ATEX approved?

Aiken ink pumps (PAB und PNB) are ATEX approved – they are correspondingly certified and marked. The respective certificates of conformity and prototype test certificates / confirmation of deposit are available for both pump series and can be requested.

Are Aiken Screw Pumps UL or CSA approved?

The drive motors conform to VDE regulations as well as European motor standards (DIN EN 60 034-1) and bear a CE mark.

Versions compliant with non-European regulations, e.g. CSA, UL or other country-specific requirements are possible.

What do you have to pay attention to when using frequency converters?

When frequency converters are used make sure that RC elements provide for interference suppression and, as the case may be, for voltage smoothing.

In principle, thermistor-type motor protection can only be achieved with the use of thermal sensors (PTC) with a corresponding tripping unit.

Are Aiken Screw Pumps suitable for use with frequency converters?

In general, our pump drives can be outfitted for operation with frequency converters.

What do you have to pay attention to in the case of different mains voltages?

Standard Aiken Pumps have to run on mains voltages conforming to IEC38.

When pumps are used with non-European electrical parameters it is necessary to remember that the frequency and voltage are in direct proportion to each other.

Pump drives and/or hydraulic elements are adjusted at the factory to make sure the required delivery parameters are reached even at different frequencies.

You can find the respective characteristics in our brochures.

What are the maximum viscosities a liquid can have?

Unless otherwise indicated, the characteristic curves shown in the brochures apply to viscosities of 1 mm²/s at a density of 1kg/dm³.

But selected types of pumps also permit higher viscosities. You can find more precise information in our brochures. The maximum viscosities amount to the following in the case of:

centrifugal pumps: 20 mm²/s

positive-displacement pumps: 2,500 mm²/s

Higher viscosities are available on request.

What is the maximum contamination permitted for a liquid?

Due to the design of individual pumps it is possible to permit varying degrees of contaminants in the liquid being pumped. So it is possible to pump clean, turbid and dirty liquids.

The following applies to centrifugal pumps: contaminant grain sizes of 0.3 mm to 8 mm are permissible, depending on the type of pump. In this respect the lower values apply to closed impellers and the higher values to open ones.

Another factor is the quantity of the contaminants found in the liquid. Here, too, the following applies: large quantities of contaminants require the use of open impellers.

The following applies to screw pumps: due to the way they work, only clean liquids without abrasive or long-fibered constituents (contaminated with a maximum grain size of 0.05 mm at a maximum of 40 mg/l) are permitted in the case of screw pumps.

For more information please contact us.

What is the maximum temperature the liquid can have?

For every type of pump there are restrictions on the temperature of the pumped liquids due to the materials used. You can find concrete information on this in the respective brochures.

Among the plastic pumps there are ones that are limited to temperatures of -30 °C to +60 °C. This range is expanded to limits of -100 °C to +150 °C by the use of a special plastic.

Limits of -30 °C to +90 °C generally apply in the case of pumps made of metal. With special version it is possible to extend this range to -70 °C to +170 °C.

What liquids is it possible to pump?

Aiken Pumps are used for a large number of industrial liquids.

They include, among others, emulsions, cooling brines, lacquers, lyes, inks that contain solvents, oils, organic solutions, cleansers, acids, lubricants, thermal oils, water (distilled or deionized) and water-based paints.

The liquids that can be used in concrete cases depend on the pump. You can find information on this in the respective brochures, or you can contact us.

Are Aiken Pumps self-priming?

Our screw pumps are self-priming due to the way they work.

Sealless Aiken immersion pumps are basically not self-priming. The 1st impeller has to be wetted for the starting procedure.

Why is it necessary to check the direction of rotation?

Due to the way they work, centrifugal pumps even deliver when they are run opposite to the specified direction of rotation. But only 1/3 of the required volumetric flow is reached. Damage to the pump due to the wrong direction of rotation can be largely ruled out.

The direction of rotation in the case of screw pumps is much more critical. They are destroyed if they are run in the wrong direction of rotation. If no liquid is delivered and there is thus no lubrication of the pump’s hydraulic system, the pump will run

"dry". The drastic increase in temperature of the hydraulic components leads to immediate and irreparable destruction of the screws and the casing’s coating.

Are all Aiken Pumps sealless?

All Aiken centrifugal pumps (immersion pumps) are sealless.

One exception is our LMP screw pumps. These positivedisplacement pumps come with shaft seals or mechanical seals to that they can work dependably even at pressures of 120 bars.

Do sealless Aiken immersion pumps have to be immersed in a tank?

All our sealless centrifugal pumps have to be immersed in a tank (not to be confused with submersible-motor pumps where the complete pump together with its motor is immersed in the liquid). Design-related leakage makes a tank absolutely necessary.

What is a sealless immersion pump?

Pumps generally require a shaft seal. These shaft seals are very sensitive to contaminated liquids and dry running. So the seal is the main wearing part of a pump.

Most pump failures are due to defective seals.

The design of sealless pumps makes it possible to dispense with a shaft seal. With these pumps the impeller sits on an extended motor shaft. Since it is used as an immersion pump, the controlled leakage remains in the tank or reservoir.

Thanks to the sealless design of Aiken immersion pumps it is possible for them to run dry to limited extent.

Aiken Pumps is one of the few manufacturers worldwide able to make sealless pumps that are reliable at operating pressures as high as 25 bars.

How does a screw pump work?

With this pump there are three screws next to each other in the discharge casing. The primary screw, or drive screw, in the middle forms the pumping cavity together with the two secondary screws when they mesh.

The rotation of the set of screws opens up cavities on the suction side which the liquid in the pump flows into. The liquid is forced via the screws’ angular momentum through the closing cavities to the pump’s pressure port.

Since this principle corresponds to a piston constantly moving in one direction, the result is an even, surge-free volumetric flow.

The maximum achievable pressure is limited by the mechanical strength of the components, but primarily by the motor power.

LMP1270GWR262P02BA, LMP1270GWR262P02BC, LMP1270GWR262P02BF, LMP1270GWR262P02BK, LMP1280GWR262P02BA, LMP1280GWR262P02BC, LMP1280GWR262P02BF, LMP1280GWR262P02BK, LMP1290GWR262P02BA, LMP1290GWR262P02BC, LMP1290GWR262P02BF, LMP1290GWR262P02BK, LMP1350GWR262P02BA, LMP1350GWR262P02BC, LMP1350GWR262P02BF, LMP1350GWR262P02BK, LMP1360GWR262P02BA, LMP1360GWR262P02BC, LMP1360GWR262P02BF, LMP1360GWR262P02BK, LMP1270GGR262P02BA, LMP1270GGR262P02BC, LMP1270GGR262P02BF, LMP1270GGR262P02BK, LMP1280GGR262P02BA, LMP1280GGR262P02BC, LMP1280GGR262P02BF, LMP1280GGR262P02BK, LMP1290GGR262P02BA, LMP1290GGR262P02BC, LMP1290GGR262P02BF, LMP1290GGR262P02BK, LMP1350GGR262P02BA, LMP1350GGR262P02BC, LMP1350GGR262P02BF, LMP1350GGR262P02BK, LMP1360GGR262P02BA, LMP1360GGR262P02BC, LMP1360GGR262P02BF, LMP1360GGR262P02BK

LMP1040GWT219Lxx, LMP1050GWT219Lxx, LMP1140GWT219Lxx, LMP2030GWT219Lxx, LMP2130GWT219Lxx, LMP2220GWT219Lxx, LMP1040GGT219Lxx, LMP1050GGT219Lxx,

LMP1140GGT219Lxx, LMP2030GGT219Lxx,

LMP2130GGT219Lxx, LMP2220GGT219Lxx,

LMP1210GWT262Kxx,LMP1310GWT262Kxx, LMP1210GGT262Kxx, LMP1310GGT262Kxx